PHYSICAL PROPERTIES OF ISO-PENTANE

| PARAMETER | UNIT | TYPICAL VALUES |

|---|---|---|

| HSN Code | 2901000 | |

| CAS Number | 78-78-4 | |

| Molar Mass | g/mol | 72.15 |

| Physical Appearance | liquid, colorless | |

| Odour | Odourless | |

| Density at 15 °C | g/cm3 | 0.625 |

| Melting Point | °C | -160 |

| Boiling Point | °C | 28 |

| Flash Point | °C | -51 |

| Vapour Pressure at 20 °C | kPa | 76.1 |

| Refractive Index | 1.3575 |

- Iso-Pentane is the first branched, liquid hydrocarbon or paraffin. This group of substances is also called alkanes. The iso-Pentane has a chemical formula of C5H12

- Iso-Pentane is almost insoluble in water, but shows very good solubility or unlimited miscibility with many organic solvents such as other paraffins, ethers, esters, aromatics or chlorinated hydrocarbons.

Application

Like all alkanes (paraffins, saturated hydrocarbons), iso-Pentane is a very good solvent for non-polar substances such as lubricating greases. However, its boiling point of 29 °C is very close to room temperature, so it is usually used elsewhere.

Very pure, aromatics-free iso-Pentane is used in shaving gel or shower gel, as it already evaporates due to body temperature, making the products foam up very finely and creamily.

Due to increasingly strict rules to protect the ozone layer and stop global warming, iso-Pentane is an ideal substitute for chlorinated and fluorinated hydrocarbons for foaming polystyrene or polyurethane.

Cyclopentane is very often used in combination with different proportions of iso-Pentane to produce Polyurethane (PU) foam. The Cyclopentane has a better insulating effect, the iso-Pentane evaporates more easily and contributes to the optimal formation of the cell structure.

Geothermal plants are a significant contribution to renewable energy supply. In this process, heat is extracted from the ground and converted into heating energy for buildings in a heat pump. iso-Pentane can be used as the process medium in such heat pumps.

- Shaving foam and shower gel

- Non-polar solvent with very high volatility

- Working medium in geothermal plants

- Blowing agent for polystyrene and polyurethane foam

- Building insulation

- Process medium for polyethylene (PE, LLDPE) and polypropylene (PP)

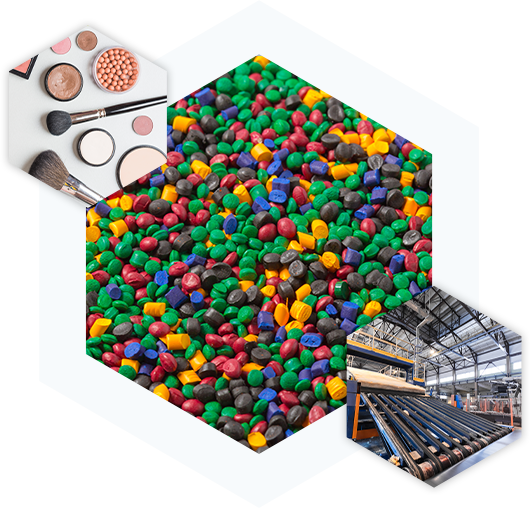

The most widely produced plastic in the world is Polyethylene (PE). Modern plants polymerize the ethylene in the gas phase. This must be cooled after the reaction so that the dust-fine plastic beads become solid and do not stick to the equipment. iso-Pentane is injected in liquid form into the gas stream. It evaporates and thus cools the reaction. The iso-Pentane can then be condensed and reused. It can also be used as a process medium for Polypropylene (PP), which is produced in the same way in the gas phase.